From Prototype to Prosperity

Bringing a PCB (Printed Circuit Board) prototype to the market mirrors the journey of starting a commercial pressure washing business, as both endeavors demand careful planning and strategic execution. Just as PCB designers meticulously craft prototypes, entrepreneurs embarking on a pressure washing venture must lay the groundwork for success. In the PCB realm, engineers work diligently to transform concepts into functional prototypes, addressing technical challenges, optimizing design, and adhering to industry standards. Similarly, when diving into the commercial pressure washing industry, entrepreneurs must plan their market entry with meticulous detail, considering factors such as target clientele, equipment selection, and pricing strategies.

Once a PCB prototype reaches the production stage, the focus shifts to scalability and efficiency. Similarly, in the world of commercial pressure washing, expansion and sustainability become paramount as businesses strive to serve a broader customer base. PCB manufacturers aim to streamline production processes to meet market demand efficiently, while pressure washing businesses must adapt to a wide range of cleaning tasks and commercial applications. The parallel between these two seemingly distinct domains underscores the significance of adaptability, growth, and the ability to pivot strategies as they evolve from prototype to a thriving commercial venture. Whether in the world of electronics or outdoor cleaning, a strategic approach is essential to successfully navigating the path from initial concepts to a robust market presence.

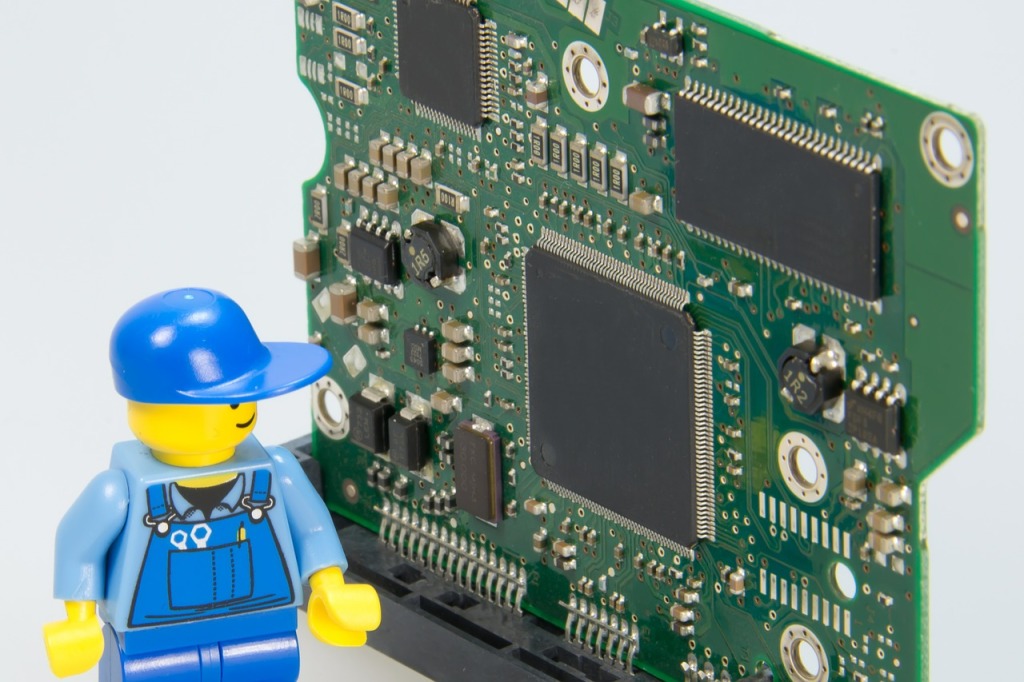

Once you have a design that you think will meet your customer demand, you can begin to think about how to create a prototype that you can take around to potential investors and stores so that they will see if it is something they wish to offer. This is an important process and it is required in order to perfect a PCB design and to move it from an idea to a marketable concept.

Prototyping a Product

Prototyping a product takes some thinking ahead. It is a big task because it requires you to think about all of the individual and technical components that will go into your invention. This article on Entrepreneur Magazine outlines the reasons that you should create an effective prototype. The article makes the point that creating a prototype for your product will allow you to adequately test the functions of your product before you push it to market, as well as to help you describe your product to potential investors or show them a sample when you are trying to raise money for your invention or product.

While it is still in the development stage, you will be able to tweak your design to fit the standards that are required to take it to market in your industry as well as to change anything that may slow down the functions of your design.

Box/System Build

The container that you put your invention in is just as important as the unit itself. Once you have established the type of engineering design you need, you will need a case to put it in. This is important to the marketability of a product. You should put some thought into this process and make sure that you have explored all of the options before taking your product to market.

Experienced box and system builders can be found on freelance sites, but we recommend choosing a seasoned design company that has a variety of skills and areas of expertise to keep your product design in one place through completion.

Cable Assembly

The cables and wires that power your unit are essential to the correct operation of your devices. They must also run a safety check that will ensure that you are making the connections with your cables to the units in a manner that will not put your customers at risk. Additionally, you need to know the specifications regarding power input and output as well as the amount of AC or DC required to power it safely.

Procurement

Procurement has to do with the process of obtaining, coordinating, and putting in place the essential processes that will guarantee the successful creation, manufacturing, distribution, and marketing of a product. If you want to have colocation of services, it is important to find a design team that also understands the procurement process so that they can help you get everything in place to provide for a successful distribution process.

Volume Assembly

When you need a large volume of items manufactured and distributed, you need the help of an established high volume organization that can meet the changing demand of your business.